Industrial:

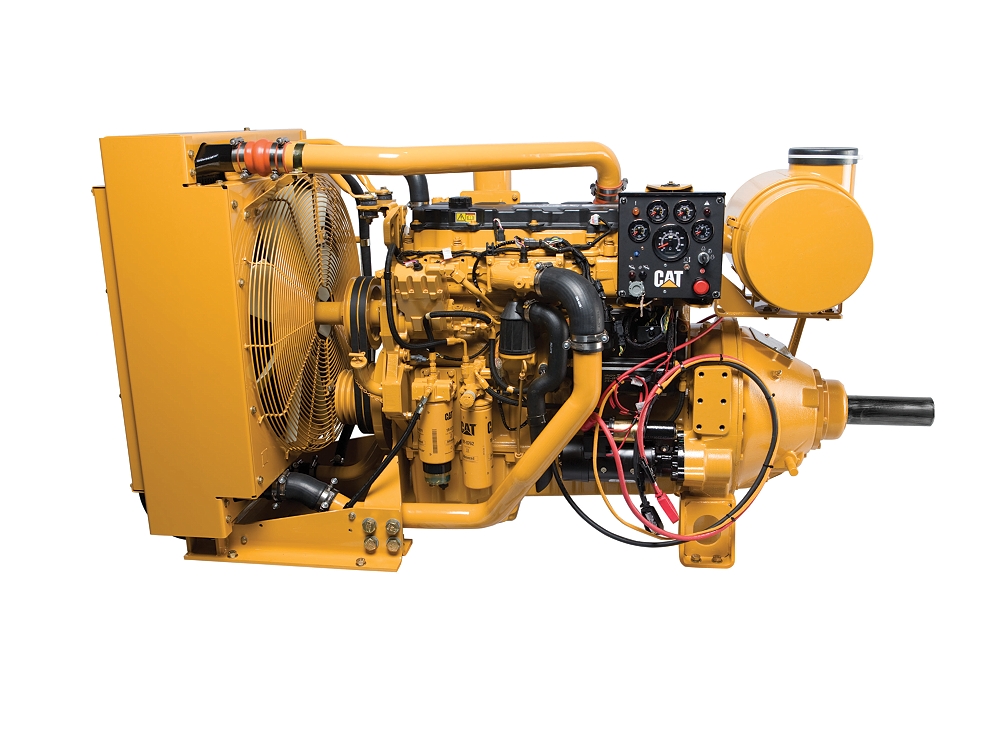

Cat® C9 Industrial Power Unit

Click a link to download the document:

- Minimum Rating

- 275.0 bhp

- Maximum Rating

- 350.0 bhp

- Emissions

- China Stage II, U.S. EPA Tier 2 Equivalent or U.S. EPA Tier 3 Equivalent, EU Stage II Equivalent or EU Stage IIIA Equivalent

- Rated Speed

- 1800-2200 rpm

The Cat® C9 Industrial Power Unit is offered in ratings ranging from 205-261 bkW (275-350 bhp) @ 2200 rpm. These ratings meet China Stage II, U.S. EPA Tier 3 equivalent, or EU Stage IIIA equivalent emission standards. Ratings: 223-261 bkW (300-350 bhp) @ 1800-2200 rpm meet China Stage II, U.S. EPA Tier 2 equivalent, EU Stage II equivalent emission standards. Conveniently pre-configured for a wide range of applications, the Cat® Industrial Power Unit is a complete power package containing a radiator, flywheel, alternator and alternator wiring completely pre-assembled for fast, straightforward installation in a number of OEM, customer and packager applications. These fuel efficient units are ready made for irrigation, industrial, mining and other pump applications.

Product Specs

-

Power Rating

- Minimum Rating

- 275.0bhp

- Maximum Rating

- 350.0bhp

- Rated Speed

- 1800-2200 rpm

- Minimum Rating

- 275BHP

- Maximum Rating

- 350BHP

- Rated Speed

- 1800-2200 rpm

- Maximum Power

- 350HP

- Rated Speed

- 1800-2200 rpm

- Minimum Power

- 275HP

-

Emission Standards

- Emissions

- China Stage II, U.S. EPA Tier 2 Equivalent or U.S. EPA Tier 3 Equivalent, EU Stage II Equivalent or EU Stage IIIA Equivalent

- Emissions

- China Stage II, U.S. EPA Tier 2 Equivalent or U.S. EPA Tier 3 Equivalent, EU Stage II Equivalent or EU Stage IIIA Equivalent

- Emissions

- China Stage II, U.S. EPA Tier 2 Equivalent or U.S. EPA Tier 3 Equivalent, EU Stage II Equivalent or EU Stage IIIA Equivalent

-

General

- Engine Configuration

- Inline 6, 4-Stroke-Cycle Diesel

- Bore

- 112 mm (4.41 in)

- Stroke

- 149 mm (5.87 in)

- Displacement

- 8.8 L (537 in³)

- Aspiration

- Turbocharged Aftercooled (TA)

- Compression Ratio

- 16.3:1

- Rotation (from flywheel end)

- Counterclockwise

- Cooling System Capacity

- 44 L (46.5 qt)

- Lube System (refill)

- 32 L (33.8 qt)

- Engine Configuration

- Inline 6, 4-Stroke-Cycle Diesel

- Bore

- 112 mm (4.41 in)

- Stroke

- 149 mm (5.87 in)

- Displacement

- 8.8 L (537 in³)

- Aspiration

- Turbocharged Aftercooled (TA)

- Compression Ratio

- 16.3:1

- Rotation from Flywheel End

- Counterclockwise

- Cooling System - Capacity

- 44 L (46.5 qt)

- Lube System - Refill

- 32 L (33.8 qt)

- Engine Configuration

- Inline 6, 4-Stroke-Cycle Diesel

- Bore

- 4.4in

- Stroke

- 5.9in

- Displacement

- 537in³

- Compression Ratio

- 16.3:1

- Aspiration

- Turbocharged Aftercooled (TA)

- Rotation from Flywheel End

- Counterclockwise

-

Power Unit Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 2174.4 mm (85.81 in)

- Width

- 987.8 mm (38.89 in)

- Height

- 2008.1 mm (79.06 in)

-

Power Unit Dimensions - Approximate

- Weight - Net Dry - Standard Configuration Without Oil, Cooling, Clutch, Compressor, A/C

- 1490 kg (3285 lb)

- Height

- 2008.1 mm (79.06 in)

- Length

- 2174.4 mm (85.81 in)

- Width

- 987.8 mm (38.89 in)

-

Power Unit Dimensions

- Weight

- 3285lb

Equipment

-

- Air Inlet System

-

- Turbocharged

- Air-to-Air Aftercooled

-

- Control System

-

- Electronic governing, PTO speed control

- Programmable ratings

- Automatic altitude compensation

- Power compensation for fuel temperature

- Programmable low and high idle and total engine limit

- Electronic diagnostics and fault logging

- Engine monitoring system SAE J1939 broadcast and control

- ADEM™ A4 Electronic Control Unit (ECU)

-

- Cooling System

-

- Thermostats and housing, vertical outlet

- Jacket water pump, centrifugal

- Water pump, inlet

-

- Exhaust System

-

- Exhaust manifold, dry

- Optional exhaust outlet

-

- Flywheels And Flywheel Housing

-

- SAE No. 1 flywheel housing

-

- Fuel System

-

- HEUI™ injection

- Fuel filter, secondary (2 micron)

- ACERT™ Technology

- Fuel transfer pump

- Fuel priming pump

-

- Lube System

-

- Crankcase breather

- Oil cooler

- Oil filler

- Lube oil filter

- Front sump oil pan

- Oil dipstick

- Gear driven oil pump

-

- General

-

- Vibration damper

- Lifting eyes

- Cold start capability to -20° C (-4° F)

- Paint: Caterpillar yellow, with optional colors available at request